Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

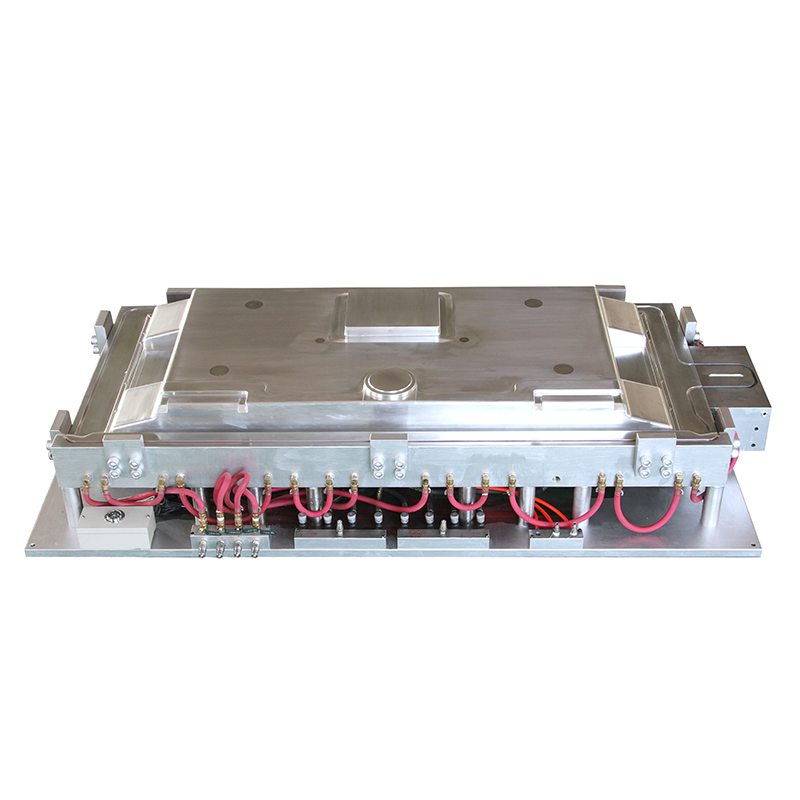

Low viscosity and low pressure allow PDCPD molds to freely design and shape, and quickly achieve product production through aluminum molds, combining equipment and molds, and operating at a low cost.

Our RIM PDCPD mold is a game-changer in the manufacturing industry, providing a seamless and efficient solution for producing high-quality PDCPD products. The low viscosity and low-pressure capabilities of this mold allow for intricate designs and shapes to be achieved effortlessly. By leveraging aluminum molds and integrating them with the required equipment, our mold streamlines the production process, ensuring quick turnaround times and cost-effective manufacturing. Whether you are in the automotive, industrial, or other sectors, our RIM PDCPD mold is designed to meet your production needs and deliver exceptional results with precision and reliability.

Versatile Design: The RIM PDCPD mold allows for low viscosity and low-pressure applications, enabling the creation of intricate and customized designs.

Efficient Production: With the ability to quickly achieve product production through aluminum molds, this RIM PDCPD mold streamlines the manufacturing process for increased efficiency.

Cost-Effective Solution: Operating at a low cost, our RIM PDCPD mold offers a budget-friendly option for producing high-quality PDCPD products.

Flexibility: The RIM PDCPD mold’s design flexibility allows for the easy shaping and customization of products, catering to a wide range of design requirements.

High-Quality Results: By combining equipment and molds, our RIM PDCPD mold ensures consistent and superior product quality, meeting the highest standards in the industry.

Here are some applications of our RIM PDCPD mold:

Automotive Industry: Our RIM PDCPD mold is widely utilized in the automotive industry for the production of various components. From body panels to bumpers and interior trim pieces, the mold’s versatility and efficiency make it an essential tool for creating high-quality automotive parts.

Industrial Equipment: In the industrial sector, our RIM PDCPD mold is a valuable asset for producing a wide range of industrial parts and components. Its flexibility and low-pressure capabilities allow for the creation of complex shapes and designs, making it suitable for manufacturing components used in machinery, equipment, and other industrial applications.

Transportation Sector: Our RIM PDCPD mold plays a crucial role in the transportation sector, particularly in the production of components for trucks, buses, tractors, and construction equipment. With its ability to quickly achieve product production through aluminum molds, the mold enables transportation manufacturers to create durable and high-quality components that meet industry standards.

Building and Construction: The building and construction industry benefits greatly from our RIM PDCPD mold, which is used to manufacture a variety of building materials and structural components. From panels to architectural elements, the mold’s design flexibility allows for the creation of lightweight and durable products that are essential for construction projects.

New Energy Vehicles: As the demand for new energy vehicles continues to rise, our RIM PDCPD mold is increasingly used in the production of components for electric vehicles and other sustainable transportation solutions.